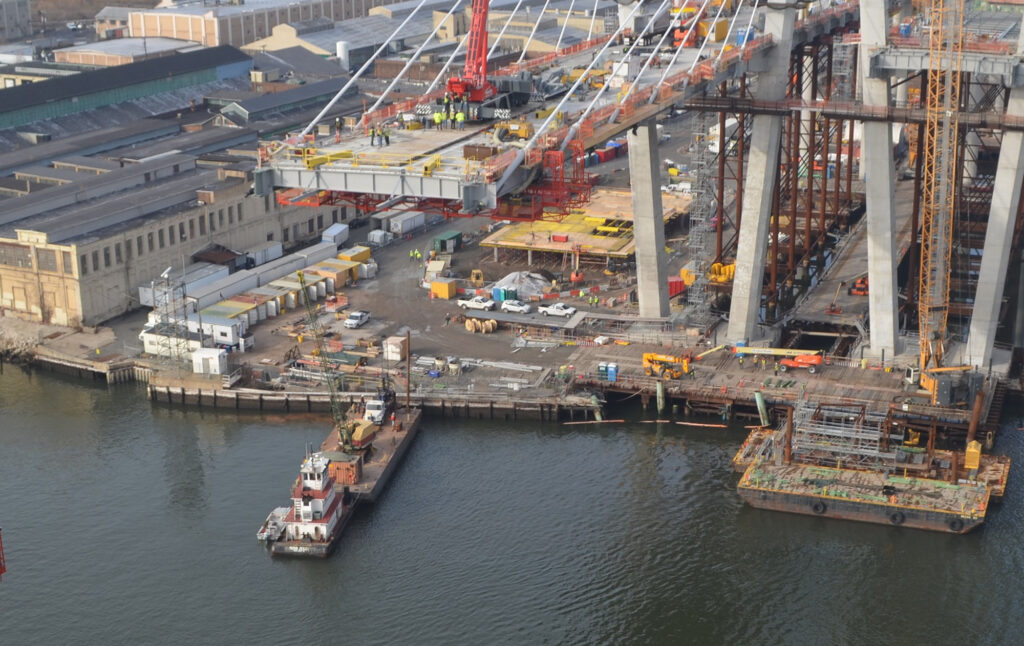

This $1.5B project involved the replacement of the two steel girder bridges, built in 1928, carrying I-278 over the Arthur Kill connecting Staten Island to New Jersey. The replacement bridge consists of 2 massive cable stay structures each carrying six travel lanes for commuters, freight carriers and a 10-foot bike path for pedestrians. The bridges and approaches span approximately 1 mile over the Arthur Kill and the New Jersey Turnpike (I-95). The two massive cable stay structures and approaches are founded on over 200 drilled shafts ranging between 5.5 and 10 feet in diameter.

Under the Port Authority’s first design-build-finance-maintain (P3) contract, Kiewit-Week-Massman retained GTR to provide Cross-hole Sonic Logging (CSL), drilled shaft consulting and remediation services of over 200 drilled shafts. A few shafts from Phase 1 had minor anomalies, but through retesting and/or alternate NDT methods, GTR was able to provide testing results and shaft re-evaluations that were accepted without significant coring or remediation.

To address NJ Turnpike shaft CSL results performed by Others, GTR performed additional testing for KWM including confirmatory CSL and Cross-hole Tomography (CT). Using CSL retests and CT results, GTR performed individual Concrete Strength Evaluations to further evaluate the shaft integrity. Where defects were confirmed by coring, GTR provided recommended repair procedures in which the defect zones were cored, flushed and repaired with high strength grout. Down-hole cameras were employed to confirm defective zones had been adequately flushed. GTR performed confirmatory CSL testing, which was used to ensure the repaired zone was filled with high strength grout. Based on GTR’s analyses, the drilled shafts were approved, thereby saving the project team additional costs and reducing months on the schedule. GTR and KWM implemented similar procedures on several Phase II shafts along the New Jersey Turnpike portion of the Project.